Pasteurization is the backbone of beverage safety and shelf stability. In the beverage industry, pasteurization works by applying controlled heat to destroy spoilage microorganisms and pathogens that shorten shelf life, cause off-flavours, and create compliance risks. Without it, even premium beverages are vulnerable to rapid product failure.

What is pasteurization?

Pasteurization is a thermal process that reduces harmful bacteria, yeasts, and moulds to safe levels while preserving taste and quality. In simple terms, it’s how beverages stay safe and saleable beyond a few days.

In industrial beverage production, pasteurization is applied to:

- Beer and cider

- RTD alcoholic drinks

- Juices and functional beverages

- Flavoured waters

- Dairy-based drinks

For plant owners, pasteurization isn’t a “nice to have.” It’s a non-negotiable production control point that directly impacts shelf life, export readiness, and brand risk.

Shelf life failures almost never happen randomly. They happen because microorganisms survive the production process.

Without pasteurization:

- Residual yeast continues fermenting inside sealed bottles or cans

- Bacteria create haze, sediment, or gas buildup

- Flavours degrade weeks earlier than expected

- Products fail QA testing or customer audits

Even with hygienic filling, cold filling alone does not protect shelf life. Microbes introduced upstream — in water, syrups, fruit bases, or packaging — will eventually win.

That’s why pasteurization is one of the most effective beverage shelf life solutions available today.

What pasteurization really changes

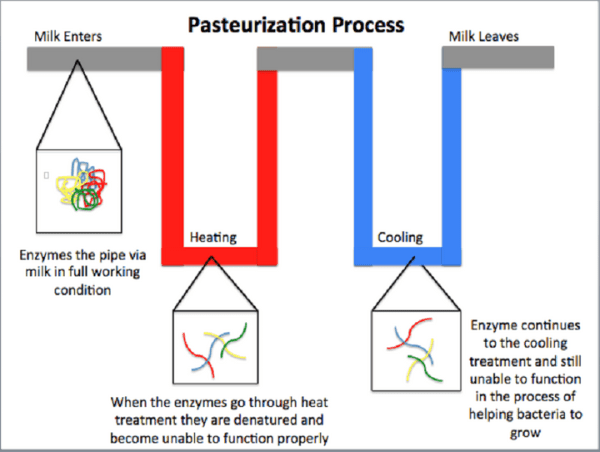

How does pasteurization actually work?

Pasteurization works by holding a beverage at a defined pasteurization temperature for a specific time. This time–temperature relationship is what determines microbial kill rate.

Common methods include:

Tunnel pasteurization

Bottles or cans are heated gradually after filling and sealed packaging passes through multiple temperature zones.

Best for:

- Beer, cider, carbonated RTDs

- High-volume, continuous production

Flash (HTST) pasteurization

Liquid is rapidly heated and cooled before filling.

Best for:

- Juices and functional beverages

- Heat-sensitive formulations

Batch pasteurization

Small volumes are heated in tanks.

Best for:

- Pilot plants

- Limited SKUs or seasonal runs

The correct method depends on product composition, throughput, packaging, and regulatory exposure.

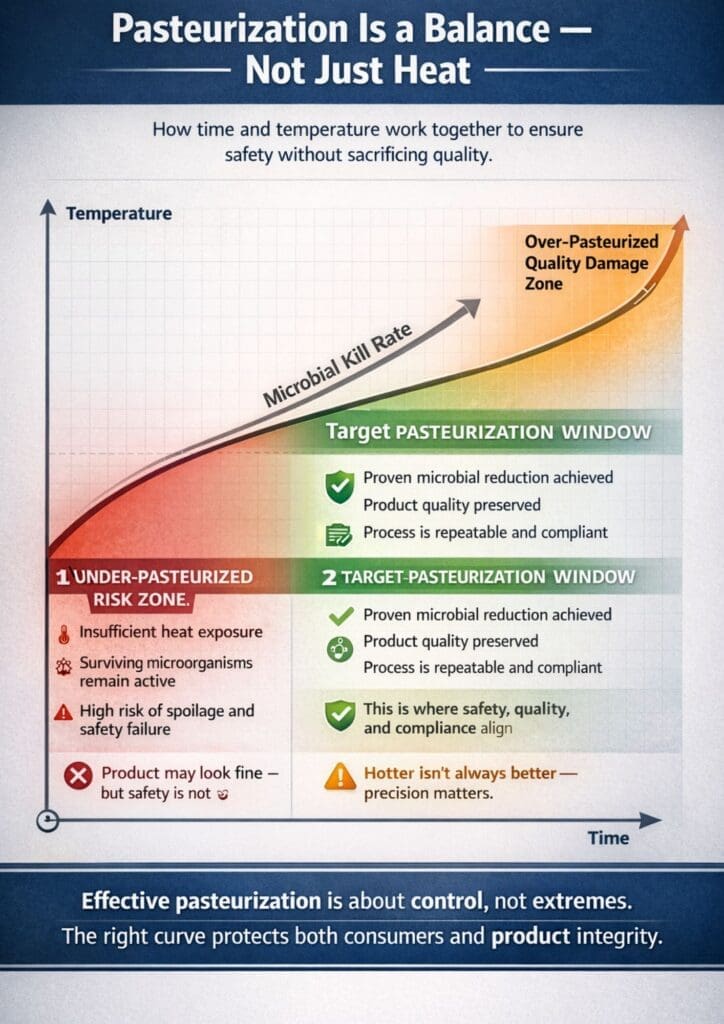

Pasteurization temperature: why “hot enough” is not enough

One of the most common mistakes manufacturers make is guessing or copying pasteurization settings.

Pasteurization temperature must be engineered around:

- Beverage pH

- Sugar and alcohol content

- Carbonation levels

- Target shelf life

- Distribution conditions (cold chain vs ambient)

Over-pasteurize and you damage flavour and nutrients.

Under-pasteurize and shelf life collapses quietly — until it doesn’t.

This is where experienced multi-discipline engineering consultants add real value: validating thermal loads, calculating pasteurization units (PU), and aligning equipment with actual product risk.

Why growing beverage plants hit pasteurization problems

Most Australian beverage plants don’t start with pasteurization issues. They grow into them.

Problems typically appear when:

- Production scales beyond manual controls

- New SKUs introduce sugar, fruit, or dairy components

- Export markets demand longer shelf life

- Retailers require guaranteed ambient stability

At AUD 10–80 million turnover, pasteurization failure isn’t just technical — it’s commercial. One recall or rejected container can erase years of margin.

Is pasteurization mandatory for beverages?

Not always by law — but practically, yes.

Regulators, distributors, and retailers increasingly expect:

- Documented thermal processing

- Validated microbial reduction

- Traceable batch data

If you’re exporting or selling nationally, pasteurization is often the simplest way to meet these expectations without relying entirely on preservatives or cold-chain dependency.

Pasteurization as a long-term shelf life strategy

Modern pasteurization isn’t just about heat. It’s about system design:

- Integrated CIP and sanitation

- Automated temperature logging

- Line speed optimisation

- Energy efficiency and water recovery

Done right, pasteurization becomes an enabler of growth — not a bottleneck.

Final thoughts for beverage decision-makers

If you’re asking what is the pasteurization role in your plant, the answer is straightforward: it’s the difference between controlled growth and unpredictable risk.

Shelf life doesn’t fail at the retailer.

It fails quietly on the production line weeks earlier.If you’re serious about protecting product integrity, exports, and brand reputation, investing in the right pasteurization strategy is one of the smartest decisions you can make.

Looking for a Proven Tunnel Pasteurization Solution?

When shelf life, export compliance, and production reliability are non-negotiable, equipment choice matters.

Sarom Global is a global supplier of high-performance co-brand tunnel pasteurizers engineered for modern beverage manufacturing environments. Headquartered in Australia and supporting EMEA, Asia Pacific, and the Americas, Sarom Global delivers complete pasteurization solutions — from system selection to installation, commissioning, and long-term technical support.

Their tunnel pasteurizers are designed for:

- Beer, RTDs, juices, dairy drinks, functional beverages, and flavored waters

- Capacities ranging from 500 to 60,000+ bottles or cans per hour

- Precise time–temperature control with automated PU monitoring

- Energy-efficient operation with integrated water and heat recovery

- Full compliance with international food safety and quality standards

Backed by European-grade components and robust automation platforms, Sarom Global’s systems help beverage producers extend shelf life without compromising taste, quality, or brand integrity.

👉 To learn more or discuss the right pasteurization system for your plant, connect directly with Sarom Global here:

https://www.saromglobal.com/contact-us/

Call: +61 2 8317 5089

Email: info@saromglobal.com

HQ: Australia | Supporting EMEA, Asia Pacific & Americas

Frequently asked Questions

What is pasteurization in the beverage industry?

Pasteurization in the beverage industry is a controlled heat treatment process used to reduce harmful microorganisms like bacteria, yeast, and mould. By applying specific time–temperature combinations, pasteurization protects product safety, stabilises quality, and significantly extends beverage shelf life without relying solely on preservatives.

Why is pasteurization important for beverage shelf life?

Pasteurization is critical for beverage shelf life because it stops microbial activity that causes spoilage, gas formation, haze, and flavour degradation. Without pasteurization, microorganisms continue to grow inside sealed packaging, leading to early product failure, recalls, or rejected shipments—especially in ambient distribution and export markets.

What happens if a beverage is not pasteurized?

If a beverage is not pasteurized, residual microorganisms can survive the filling process and multiply over time. This often results in shortened shelf life, off-flavours, visible spoilage, over-carbonation, or packaging failure. These issues usually appear weeks later, making them costly and difficult to trace back to production.

What is the correct pasteurization temperature for beverages?

There is no single correct pasteurization temperature for all beverages. The required temperature depends on factors such as pH level, sugar content, alcohol percentage, carbonation, and desired shelf life. Effective pasteurization balances microbial reduction with product quality, using validated time–temperature profiles rather than fixed heat settings.

Does pasteurization affect the taste or quality of drinks?

When properly engineered, pasteurization has minimal impact on taste or quality. Problems occur only when beverages are over-pasteurized or poorly controlled. Modern systems are designed to preserve flavour, colour, and nutrients while still delivering the microbial stability needed for long shelf life and regulatory compliance.

Can beverages achieve long shelf life without pasteurization?

Some beverages can achieve limited shelf life without pasteurization by using preservatives, sterile filtration, or strict cold-chain distribution. However, for ambient storage, exports, or complex formulations, pasteurization remains the most reliable and scalable beverage shelf life solution, reducing risk while supporting consistent product quality.