Process Plant Optimization With POSy-System

Our plant optimization processes also include POSy-SystemTM, as part of our business alliance with Paradox Engineering & Technology Canada, SERVICES | pent (paradoxengtech.com). The POSy-SystemTM optimization methodology is a true multivariable orthogonal resolver whereby it solves for the most optimal of a set of multivariable Set Points, Outputs, System Gain, and Nonlinear Relationships or other Disturbance Variables. POSy-SystemTM can be integrated within existing Distributed Control Systems (DCS’s), Programmable Logic Controllers (PLC’s), and in existing Advance Process Control (APC’s), and works as an APC / Optimisation numerical engine.

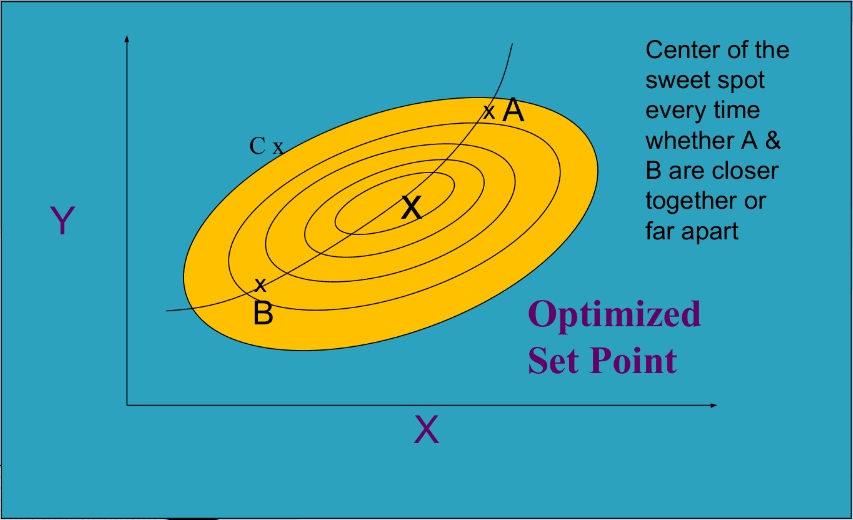

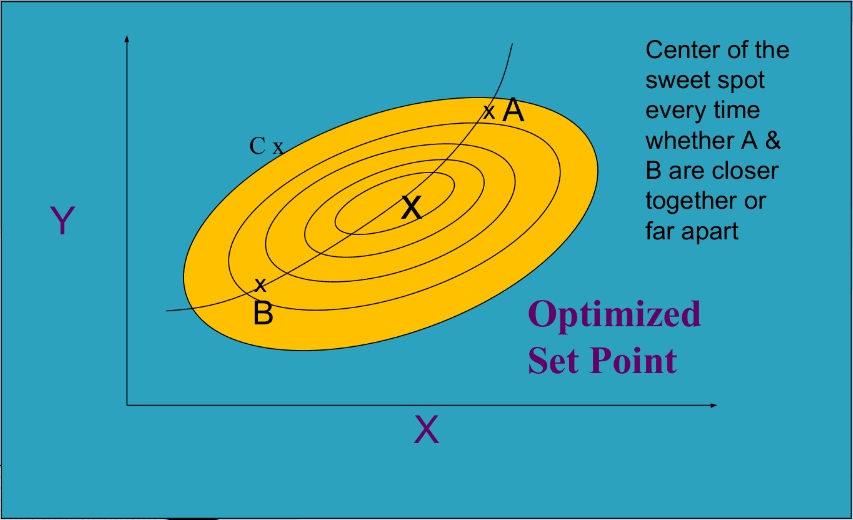

The diagram below illustrates 3 Controlled Variable set-point trials, where A, B & C are considered from other influential strategies to determine the desired true Optimized Set Point X. POSy-SystemTM solves for all of the Optimal Set Points simultaneously over the defined operational scenarios.

Problems With Existing Systems :

- 3 existing systems – experiential, statistical, and predictive methods

- All of these systems are not precise

- Large errors are generated (predictive method)

- Time consuming and therefore very costly

- Dynamic changes cannot be captured

- No guarantees – you get what you get

Alleviation of Problems:

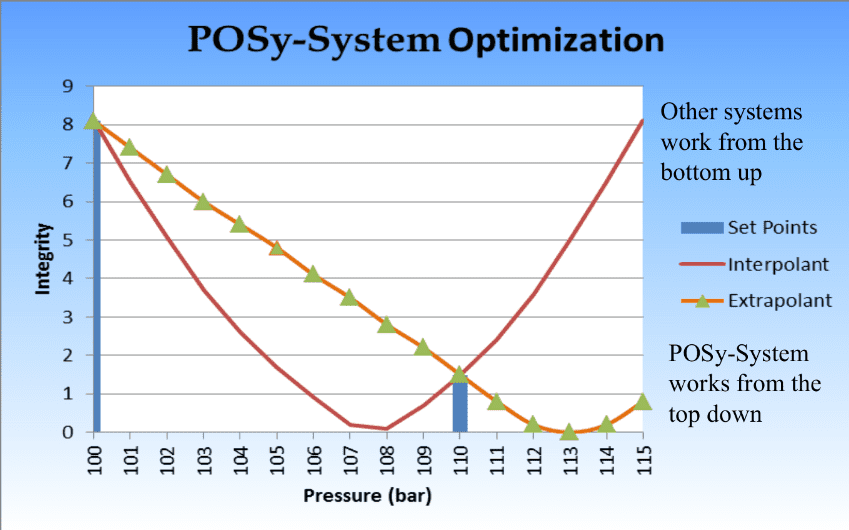

- Work from the top down instead of bottom-up

- About 10 x faster (cost-effective) than traditional methods

- Solutions are much more precise with 95-percentile accuracy

- Error generated is minimized

- System more easily adaptable to dynamic fluctuations and trends can be determined

- Increases efficiency/productivity,

- Improves quality and reduces waste all at the same time

- Provides an excellent Return On Investment (ROI) for consumers (and investors)

- Considered disruptive technology

- Guaranteed improvements

How does it work?

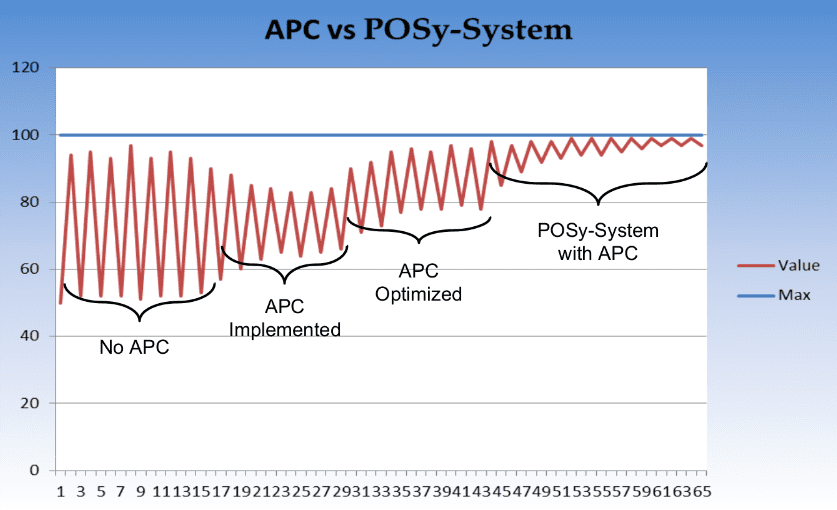

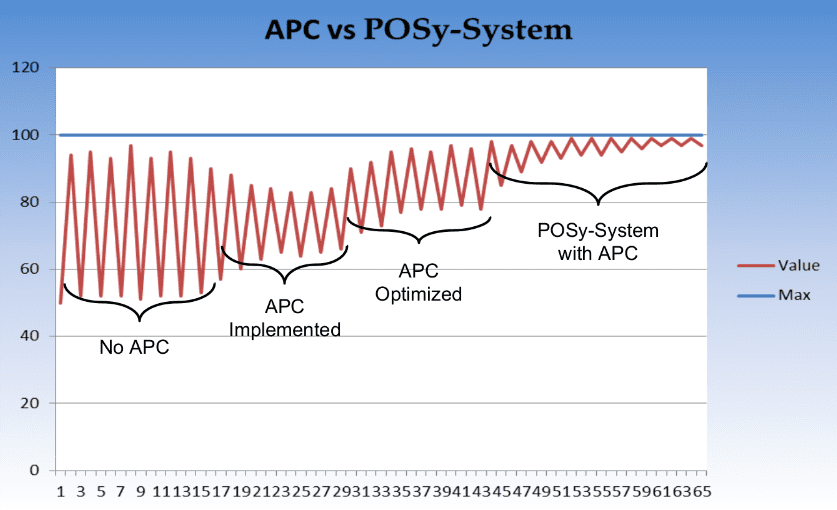

Advanced Process Control with POSy-System

What processes have been tested?

- Most testing has occurred for manufacturing – non-Newtonian fluids (non-linear systems): achieved 12% to 23.5% efficiency improvements

- Have worked with modelling software in industry: thermodynamic modelling software – works well

- Have worked with modelling software at U of A: simple mixing (works well); SAGD (works well); and Tennessee Eastman Process & HYSYS (works well)